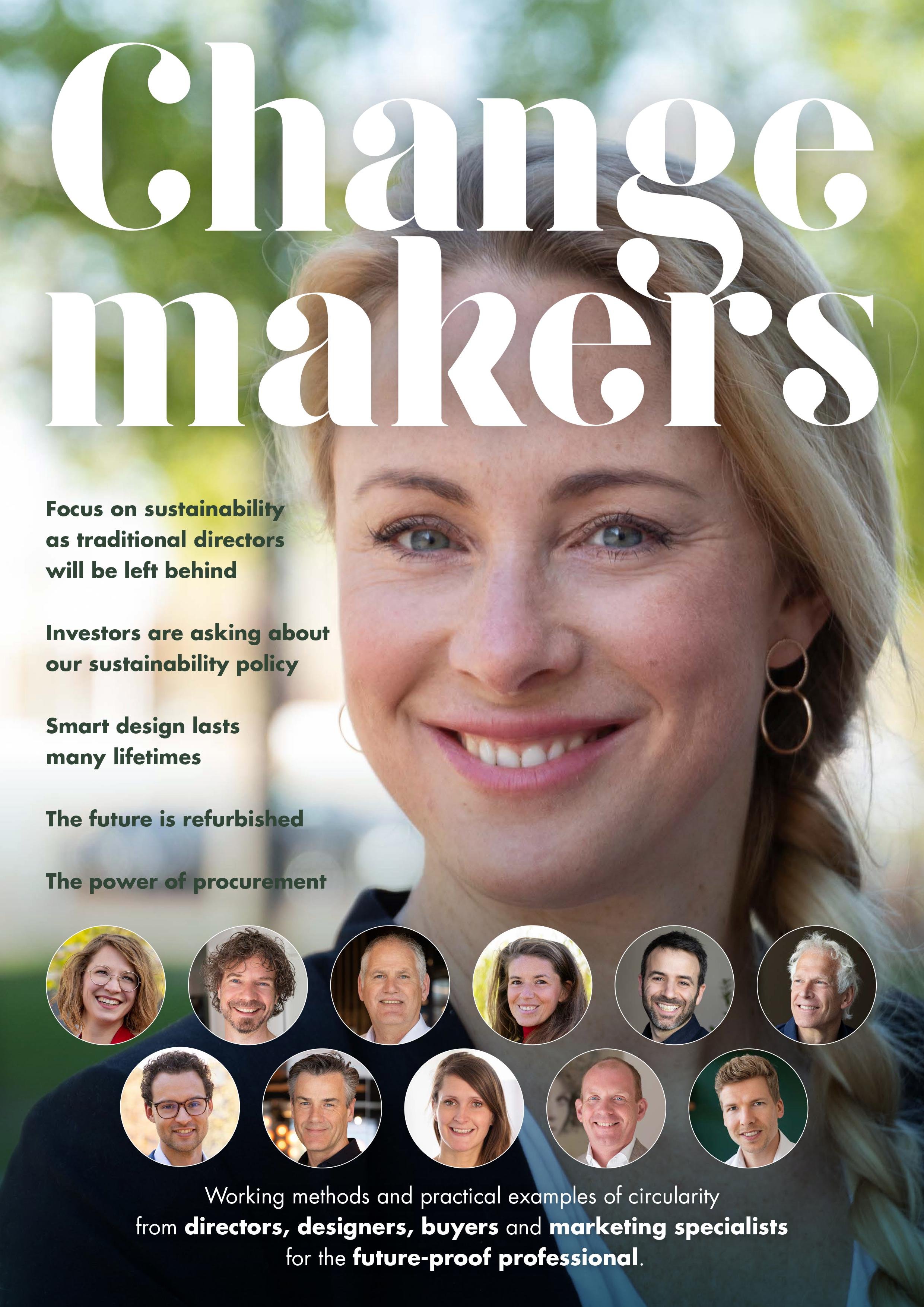

The power of procurement

Evelien van den Bossche - Compliance Officer Sustainable Procurement

The infrastructure we rely on for endless streaming has a major impact on the environment. According to Evelien, the key to making the telecom sector more sustainable lies in procurement. By incorporating circularity into our procurement policy, KPN is working on major sustainable ambitions.

People often do not view the telecom sector as an industry that significantly impacts the environment. In that context, their minds tend to go to factories with smoking chimneys, not data centres. But we’re seeing an exponentially increasing demand for data due to all the music and video streaming as well as meetings that are now held via video conferencing. KPN meets this demand through data centres full of electronic equipment, towers and thousands of kilometres of underground cables. The environmental impact of all these raw materials and the consumption of electricity and water compels us to reflect and take steps to make the telecom sector more sustainable. KPN’s ambition? To reduce our total energy consumption, use more green energy and virtually eliminate our waste.

What is the buyer’s role in circular procurement?

In practice, we’ve noticed that success is usually achieved by bringing the various parties in the chain into contact. The buyers have a pivotal role here. Given their advisory role, they can discuss circularity within the company and with the external suppliers. The buyers are aware of the social trends and market developments, know their suppliers’ circular ambitions and are familiar with the questions and wishes of internal clients. By asking the right, critical questions and actively engaging in conversation, buyers are able to translate the circular ambitions and business strategy for the chain. For us, this has resulted in contracted products that not only meet our financial and technical requirements, but that also contribute to our sustainability ambitions.

What knowledge and information do buyers need to accomplish this?

For training purposes, we sought cooperation with the Dutch procurement knowledge network NEVI and our buyers completed the ISO 20400 Sustainable Procurement training course, among others.

For the most accurate information about suppliers, we use the EcoVadis CSR assessment. This independent party has collected and verified sustainability information from approximately 50,000 suppliers worldwide. This way, we know whether we’re dealing with a sustainable party at the level of the company. The next step is to create material passports for products — the modems, remote controls, transmission towers, but also those grey boxes on the street — so we can measure in detail and improve the (material) composition and environmental impact. These are important steps to boost our circular target for 2025: that 100% of all the parts and raw materials of the consumer equipment network can be reused or recycled.

Our next step is to work in a more data-driven way. To this end, we use publicly accessible data, such as data on the water or air quality of a particular region, as well as data on breaches of the working conditions. These data assist us with the supplier selection. Linking the data with the analyses gives us considerable insight into our sustainable footprint, which can incite us to make other decisions about suppliers. This requires different competencies in a buyer: more advanced ‘soft’ skills along with the ability to analyse, advise and bring parties together.

““The environmental impact of raw materials, electricity and water consumption requires the telecom sector to become more sustainable.””

Initially, you did not include any strict circular requirements in your contracts for suppliers. How did you address this?

In partnership with our suppliers, we drafted a circular manifesto. This manifesto highlights our mutual commitment to examining where and how we can increase our sustainability, within what timeframe and which chain partners are needed.

Think of improvements in the reduction, reuse and recycling of materials and energy efficiency. A manifesto like this does not contain strict, unilateral requirements, but it does have firm ambitions, and it ensures that suppliers are willing to collaborate.

Another thing that helps here is including a research institute in the manifesto, so that the mutual efforts for sustainability remain in the research sphere. Together with the Delft University of Technology, we organise workshops with suppliers from a range of sectors to promote knowledge transfer, which makes the chain more sustainable. KPN is a relatively small party, and this makes it easier for large suppliers to jointly research sustainable solutions under the radar.

To encourage ourselves and the suppliers to put these good intentions into practice, we turned the launch of the manifesto into a press event. This meant we created external pressure that would motivate us to achieve our targets. More and more suppliers are now able to make circular deliveries and receive product returns. So, we’re now ready to include circular requirements in the contracts. As a result of this intensive cooperation among the chain parties, we’ve already achieved several successes. One example is the latest television receiver and remote control. The cover of the receiver is made of nearly 90% recycled plastic, while the remote control’s black underside is 100% recycled plastic. Last year, together with our partner, we reused and/or recycled 76% of all the modems and cable boxes. This not only has a less negative impact on the environment — we have yet to do a precise CO2 calculation — but it also saves costs because the return and repair process is cheaper than manufacturing a new product.

How have you embedded circularity in the procurement process?

Suppliers who want to work with us must start by meeting our requirements in terms of corporate social responsibility, such as environmental requirements, human and labour rights and sustainability. We’ve drawn up the CSR requirements together with other telecom parties according to international standards and guidelines from the International Organization for Standardization, the core conventions of the International Labour Organisation and the Charter of the United Nations, among others. All of the requirements are in our Supplier Code of Conduct, which suppliers must sign. To get a better feel for the suppliers, we ask them about their environmental policy, whether they measure CO2 emissions, etc.

““We publicly accessible data assist us with the supplier selection.””

It is essential that we understand how circular the products are that we purchase. As part of the tender process, the parties complete a circularity questionnaire including questions about the materials used in the products, how easy it is to repair the products, whether the supplier provides spare parts and the recyclability of the materials. To verify the responses, we literally ask for a product’s ‘bill of materials’. In addition, we ask questions about the product’s life cycle. We want to postpone the end of a product’s useful life for as long as possible, or preferably prevent it. But at some point, for example, a modem becomes outdated and is returned to us. Before we enter into business with a supplier, we ask about their return policy and have them report their figures for what has actually been returned and recycled. This allows us to be reasonably sure that everything we return is actually reused or recycled, instead of being tossed onto the rubbish pile. Finally, we ask suppliers questions about their energy consumption and the energy efficiency of their equipment. The answers to all the questions are converted into a circular score, and we can enter into a relationship with the supplier if the score is sufficiently high. This process is not yet automatic. For each project, a steering committee carefully weighs the qualitative and quantitative score and the underlying evidence.

How can you be sure your suppliers are actually meeting the standards and requirements?

““We literally ask for a product’s ‘bill of materials’ “”

We’ve joined forces with several international telecoms in the Joint Audit Cooperation, a partnership in which we jointly audit suppliers. On behalf of our competitors, we perform sustainability audits on our shared suppliers and vice versa.This enables us to further enhance our impact. In this context, we also exchange knowledge and experience in the field of corporate social responsibility and collaborate with groups like the Ellen MacArthur Foundation, the ISO and the ITU sector association to make the chain more sustainable. Together, we’ve crafted a set of criteria for sustainable telecom tenders. These criteria provide clarity for telecom suppliers worldwide and, as far as we’re concerned, they will become the global standard.

What obstacles do you run into during the procurement process while working to become more circular?

We need to evolve from a linear to a circular model. This requires the cooperation of all the parties in the chain, which is a challenge. But this is particularly helpful for gaining a better understanding of where all raw materials and parts come from. Rather than talking to each individual supplier, it’s important that everyone shares their knowledge and experiences in order to jointly develop more sustainable solutions throughout the chain.

KPN is a leading telecommunications IT provider and market leader in the Netherlands. KPN focuses on both private customers and business users, from small to large, and is connecting everything and everyone in an innovative, simple, reliable and sustainable way. KPN is one of the world’s greenest companies. To maintain this position, they’ve set far-reaching goals for the future, as they see it as their duty to use less energy and raw materials.

Lees hier het hele magazine ‘de Verschilmakers’ Nederlands bedrijfsleven.